High Mast Panels

MOQ : 1 Piece

High Mast Panels Specification

- Thickness

- 1.6 mm to 2.0 mm

- Cover Material

- Powder Coated Steel

- Current Rating

- Up to 400 Amp

- Rated Insulation Voltage

- 690V

- Base Material

- CRCA Steel Sheet

- Cooling System

- Natural Air Cooled

- Features

- Weather Resistant, Tamper Proof, Lockable, User Friendly

- Rated Operation Voltage

- 415V

- Control System

- Analog/Automatic Timer

- Protection Class

- Class I

- Way

- Multi-way (4, 6, 8, 12 way)

- Rated Current

- Up to 400A

- Protection Level

- IP65

- Connectivity Type

- Hardwired

- Cabinet Material

- CRCA Steel

- Panel Type

- Outdoor/Weatherproof Panel

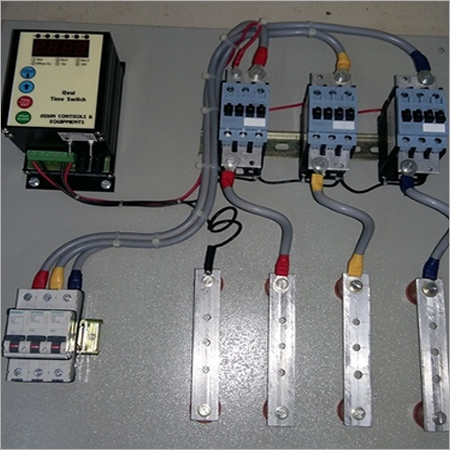

- Components

- MCB, Timer, Contactor, Push Button, Fuse, Indicating Lamps

- Operating Voltage

- 415V AC

- Product Type

- High Mast Control Panel

- Material

- CRCA Sheet Steel

- Surface Finish

- Powder Coated

- Standard

- IEC 61439 / IS 8623

- Surface Color

- Light Grey (RAL 7035)

- Rated Voltage

- 415V AC

- Frequency (MHz)

- 50 Hz

- Maximum Output Current

- 400A

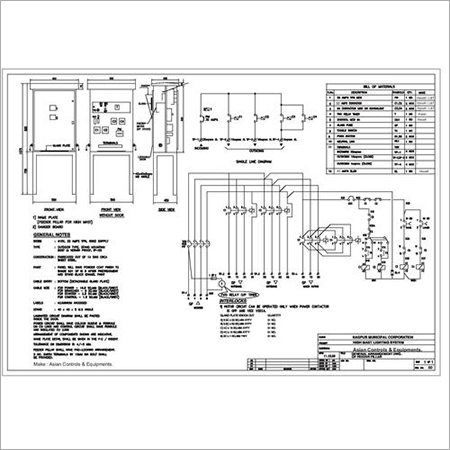

- Dimension (L*W*H)

- Custom as per Mast requirement

- Application

- High Mast Lighting, Highway Lighting, Stadium Lighting

- IP Rating

- IP65

- Ambient Temperature Range

- -10°C to +50°C

- Busbar Material

- Copper/Aluminum (as per spec)

- Service Life

- > 20 years

- Auxiliary Supply

- 230V AC

- Door Type

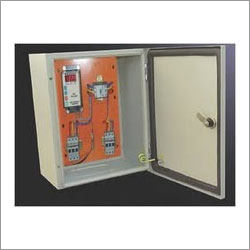

- Single/Double door with gasket

- Insulation Resistance

- Minimum 100 Mega Ohm

- Cable Entry

- Top/Bottom Cable Entry

- Wiring Standard

- ISI Standard Color Coding

- Safety Features

- Interlocking System, Overload Protection

- Relevant Document

- Wiring Diagram and User Manual provided

- Mounting Type

- Floor mounted or Wall mounted

- Panel Weight

- Varies as per configuration

- Earthling Provision

- Dedicated Earthing Terminals

- Fault Indication

- LED indicators for Faults and ON/OFF

- Timer Type

- Digital/Mechanical available

- Finish Type

- Textured Powder Coating

- Enclosure Type

- Weatherproof Outdoor Type

- Door Accessories

- Chrome Plated Locks & Hinges

- Power Source

- AC Mains

About High Mast Panels

The unparalleled range of High Mast Panels are exclusively used in areas such as rural areas, industrial compounds, hospital, high way road, city roads, housing society, school, and college. This range of High Mast Panels is well-known for utilizing both grid and solar power. Moreover, these products are featured with sturdy construction, high performance, low maintenance and long functional life. We have developed a trustworthy vendor base to procure superior quality raw material to fabricate this array of products.

Weatherproof and Versatile Design

Engineered for outdoor use, these panels incorporate IP65 protection, supporting applications in all climates. The floor- or wall-mounted design with textured powder coating and light grey (RAL 7035) finish protects internal components from dust, water, and corrosion.

Comprehensive Safety and Control Features

Safety is prioritized with dedicated earthing, interlocking systems, overload protection, and ISI standard color-coded wiring. Fault indication via LED lamps and choice of digital or mechanical timers enable both analog and automated control for reliable lighting management.

Customizable to Meet Your Requirements

Panels are available in multiple ways (4, 6, 8, 12), various busbar materials, and with single/double-door options. Dimensions and cable entry points are fully customizable, ensuring a perfect match for specific mast configurations or project needs.

FAQs of High Mast Panels:

Q: How do I select the right mounting type for a High Mast Panel installation?

A: Choose floor-mounted panels for ground-based accessibility or wall-mounted panels for limited ground space or elevated installations. The selection depends on site layout, accessibility requirements, and available mounting surfaces.Q: What safety features are integrated into these High Mast Panels?

A: Panels include an interlocking system, overload protection, dedicated earthing terminals, chrome-plated lockable doors, and robust weatherproof enclosures. These features work together to ensure user safety and reliable operation in outdoor environments.Q: When should I opt for copper versus aluminum busbars?

A: Copper busbars offer higher conductivity and are best for high-load, sensitive applications, while aluminum busbars are a cost-effective choice for standard loads. Selection is typically guided by electrical specification requirements and budget.Q: Where can these panels be installed, given their protection rating?

A: With an IP65 rating and weatherproof construction, these panels are suitable for outdoor environments such as highways, stadiums, and high mast lighting locations, ensuring safe and consistent performance in harsh weather conditions.Q: What is the process for cable entry and wiring in the panel?

A: Panels support both top and bottom cable entries. Wiring follows ISI standard color coding, and a wiring diagram is provided to ensure correct and compliant installation. Dedicated terminals are available for both power and earthing connections.Q: How do the digital and mechanical timers benefit lighting control?

A: Digital and mechanical timers automate the operation of lighting circuits, enabling scheduled switching on/off and minimizing manual intervention. This helps in energy management and extends the service life of connected lighting systems.Q: What documentation is provided for installation and maintenance?

A: Each panel includes a detailed wiring diagram and a user manual, guiding proper installation, safe operation, and routine maintenance procedures to ensure long-term reliability and compliance with relevant standards.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Street Light Control Panel Category

GST : 27AAAFA8323L1ZF

No. 114, Swapnapoorti, Jerbai Wadia Road, Parel,Mumbai - 400012, Maharashtra, India

Phone :08045802130

|

|

ASIAN CONTROLS & EQUIPMENTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry