Paperless Recorder

Paperless Recorder Specification

- Connectivity Type

- Ethernet, RS485, USB host

- Temperature Range

- -10C ~ 60C

- Measurement Range

- Configurable (varies with input selected)

- Sensor Type

- Universal input: Thermocouple, RTD, mA, V, mV

- Flow Rate

- Configurable (by input)

- Equipment Type

- Paperless Chart Recorder

- Humidity %

- 10% to 85% RH (non-condensing)

- Current Range

- 4-20 mA, 0-20 mA

- Pressure Range

- Dependent on input sensor (configurable)

- Capacity

- Internal memory up to 256MB

- Frequency

- Selectable, up to 60 Hz

- Resolution

- 0.01 unit

- Material

- Industrial grade ABS plastic body

- Power Supply

- 100-240V AC, 50/60 Hz

- Power Consumption

- Less than 20 VA

- Accuracy

- 0.2% FS

- Display Type

- Large TFT color touch screen

- Range

- input: Selectable by sensor type

- Firmware Upgrade

- Via USB or network

- Data Storage

- Up to 2 years with USB expansion

- Recording Interval

- Selectable from 1 sec to 60 min

- Alarm Output

- Up to 8 relay outputs

- Operation Mode

- Continuous/Batch selectable

- Ingress Protection

- IP65 front panel

- Mounting Type

- Panel mounted

- Analog Output

- 4-20 mA (optional)

- Input Type

- Universal (T/C, RTD, mA, V, mV, ohm)

- Weight

- Approx. 2.5 kg

- Display Resolution

- 800 x 480 pixels

- Data Export

- CSV/Binary via USB or Ethernet

- Number of Channels

- 4, 8, 12, 16 (selectable)

About Paperless Recorder

Since 1990, we have been offering our clients premium quality Paperless Recorder that is designed and manufactured by skilled team members using excellent quality basic material and cutting-edge technology in tune with the industry standards. This device is utilized as data acquisition product for the purpose of addressing most industrial recording requirements. Available in varied specifications, this Paperless Recorder is delivery to clients within promised time-frame.

Key features

- Small truly potable data logger

- 12 universal analog inputs( RTD, Thermocouples, 0-5Vdc, 0-20mA or 4-20mA signal inputs)

- Individual Hl/LO Alarm set points shown with color toggling on display.

- Alarm relay outputs with optional DIN rail mounting relay module.

- Configured via large easy-to-read Multicolor 5.7 inch graphical TFT Display, resolution 640x480 pixels.

- 0.2% accuracy

- USB connectivity.

- 10M / 100M Ethernet connectivity

- Non volatile storage up to 7000 readings per channel.

- Supplied with PC based Data acquisition software

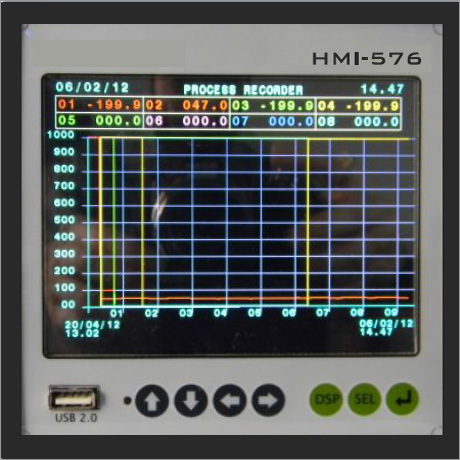

The HMl-576 is versatile general purpose universal input data logger with 12 analog inputs channels to measure process input signals from temperature sensors , humidity sensors, 0 - 5 Vdc or 4 - 20 mA signals from pressure sensors. The logging is automatically triggered at pre-programmed time intervals. A variety of communication ports are included like RS-232 or RS-485, USB 2.0 and 10/1ooM Ethernet port, Parallel or Printer port. This enables data transfer from logger to any external devices.

It is a small, truly portable logger which also suitable for panel mounted installations. Easily programmed via the seven integral push buttons and large graphical TFT display and with basic accuracy of 0.2% FSD. The HMl-576 is able to fulfil many routine data logging needs, including more demanding applications.

HMl-576 Technical specifications

|

No. of analogue channels |

12 channels. |

|

Universal Input |

Yes |

|

Voltage ranges |

0-5 Vdc Single ended.; Range and scale User Programmable |

|

Current ranges |

0-20mA, 4-20mA. Range and scale User Programmable |

|

Thermocouple Ranges; Differential and Single Ended All T/C with built-in cold junction compensation of Accuracy 0.5 degree celsius. |

0 to 1200oC - J type |

|

0 to 1800oC - B type |

|

|

0 to 1372oC - K type |

|

|

0 to 1300oC - N type |

|

|

0 to 1768oC - R type |

|

|

0 to 1768oC - S type |

|

|

0 to 400oC - T type |

|

|

Pt100/1000, 2-wire , 3-wire |

-200 to 300oC |

|

Internal reference temperature |

-50 to 150oC |

|

Alarm Outputs |

Alarming signals for 4 relays configurable. |

|

A/D Resolution |

12 bit successive approximation. |

|

Accuracy |

0.2% FSD of range. |

|

Averaging |

Provision for 4 channel averaging. |

|

Historical trends |

Yes, Distinct color for each ch.on TFT and in PC software for programmed duration. |

|

Data Scaling |

Yes |

|

Data Statistics |

Yes from within Data acquisition PC software |

|

Data Sampling |

125 milliseconds for each channel, |

|

Memory Internal |

400 MB (1 to 112000 readings) |

|

Display |

5.7 inch multicolor TFT graphical display with LED backlit. VGA (Resolution 640 X 480 pixels). |

|

User Interface |

Sensitive touchscreen resistive type; 7 tactile push button keypad. USB interface to connect external mouse and keyboard. |

|

Internal Battery for storage |

One 3V Lithium cell, easily replaceable. |

|

Totaliser |

Two 5 digit totalisers with recording and trending on the screen. |

|

Battery life |

Up to 5 years. |

|

Networking |

10M / 100M Ethernet port, TCPIP protocol to communicate with PC, Device IP settable. |

|

USB Port |

USB 2.0 Host, can connect external BGB pen drive. |

|

Serial Communication port |

RS-232 or RS-485 Factory setted. |

|

PC Setup |

Yes, with dedicated data acquisition software. |

|

Front Panel setup |

Via 7 integral keys. All essential functionality available via key pad e.g. RTC set Print time set, program input type, memory store, copy etc. |

|

Stored setups |

6 |

|

Operating temperature |

0 to 55oC |

|

Dimensions |

W-144 x H-144 x D-80 mm, Weight 0.7kg , Flush Panel Mounting type |

|

Panel cutout |

W-138 x H-138 mm. |

|

Power Supply |

100-260 Vac, 50Hz +/-10%. |

|

Enclosure Safety |

IP-65 for Front panel only.. |

|

lsolation- Channel to Channel, Channel to earth |

Up to 300V RMS AC |

|

Terminal connection |

1.5mm sq. detachable terminal strip. |

Comprehensive Multi-Channel Monitoring

Adapt to varying process requirements with selectable channelschoose from 4, 8, 12, or 16 to monitor multiple signals simultaneously. Universal input acceptance means compatibility with thermocouples, RTDs, mA, V, mV, and ohm, ensuring flexibility for numerous applications in manufacturing, energy, or chemical processing plants.

Reliable Long-Term Data Storage

Store up to two years of process data internally (256MB) with further expansion available via USB. Efficiently access records using CSV or binary export through USB or Ethernet, facilitating seamless data analysis and traceability to comply with regulatory demands.

User-Friendly, Durable Operation

The recorders large TFT color touchscreen (800 x 480 pixels) provides a clear, interactive interface. Its IP65-rated front panel shields against dust and splashes, while simple firmware upgrades via USB or network keep your system up-to-date without hassle.

FAQs of Paperless Recorder:

Q: How does the Paperless Chart Recorder manage data export and backup?

A: The recorder allows data export in CSV or binary formats directly via USB or Ethernet. Internal memory can store records for up to two years, and USB expansion ensures further capacity for backup or transfer.Q: What types of sensors and input signals are compatible with this device?

A: It works with universal input types including thermocouple, RTD, current (4-20 mA, 0-20 mA), voltage, milli-voltage, and resistance. This provides flexibility to use sensors best suited for temperature, pressure, flow, or general process monitoring.Q: When should I perform a firmware upgrade, and how is it done?

A: Firmware upgrades are recommended when new features or security improvements are released. Upgrades can be conducted easily via USB or network, ensuring minimal downtime and up-to-date functionality.Q: Where can this recorder be installed, and what is its environmental tolerance?

A: The product is designed for panel mounting in industrial environments, with an IP65 front panel for dust and splash protection. It operates efficiently within a temperature range of -10C to 60C and 10% to 85% non-condensing humidity.Q: What benefits does continuous versus batch mode operation offer?

A: Continuous mode provides uninterrupted monitoring and recording, ideal for ongoing processes, while batch mode is suitable for distinct production runs, enabling separate data files for each batch for analysis and compliance.Q: How are alarms and notifications managed for critical events?

A: The recorder supports up to eight relay alarm outputs, which can be configured based on process parameters. This facilitates real-time alerts for operators and integration with external control systems.Q: What is the accuracy and resolution of the recorded data?

A: This device offers an accuracy of 0.2% FS, with a measurement resolution as fine as 0.01 units, ensuring high-quality, precise data essential for process control and quality assurance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

GST : 27AAAFA8323L1ZF

|

|

ASIAN CONTROLS & EQUIPMENTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry